O.k. I’m pretty patient, fairly detail oriented, and my father is a fantastic woodworker(unfortunately completely uninterested in miniatures)…so why am I so miter challenged? Why can I not get my picture frames to come out properly square and neat? I hate those tiny little gaps in the corners!

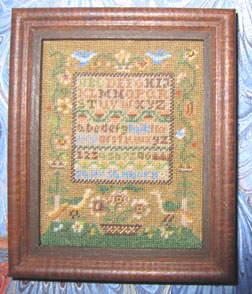

1/12 scale adaptation of a New Hampshire sampler in a frame greatly improved with a little putty and some creative faux painting.

I’ve got a couple of miter boxes, several saws, a chopper thing that cuts angles with a single plunge of a sharp razor blade and a gadget that supposedly will sand pieces at specific angles and I’ve got to tell you, I think the gadgets are a waste of money. First off, unless I’m really missing something, the chopper thing only cuts the end of a piece, so you can’t cut a lovely angle on one end, then move the piece on through and cut the other angle without first cutting the piece to length and then turning it around to nip off the end at the correct angle. Which, let me point out requires you to remove the angle guide to cut the piece to length, then replace it on the other side of the chopper before making the second angle cut. Yes, you can just flip the piece of wood over, but nice picture frame molding is not flat on both sides so holding the piece square on its top side will be a bit tricky. For the actual cutting, the chopper doesn’t work too badly on soft, fairly thin pieces of wood, but with something thicker and more dense, the angles are not cut completely ‘square’, the downward pressure of the blade ends up forcing the cut out of line to at least some degree.

And the sander gadget? I was completely disappointed on opening it to discover that all the angle guides were made out of plastic and the adjustable angle guide, also plastic, has no angle markings on it at all, and to use it you must hold it in place in the little channel it sits in along with the piece you’re trying to sand-and hopefully that piece is long enough to span that same channel without tipping into it thus giving you a whole other angle altogether. Yeah, pretty much useless.

O.k. so we’re back to the miter boxes. The metal ones come with little channels to supposedly match the width of your wood strip and hold it in place. Not always successfully, plus I’m sure the metal can’t be all that good for the longevity of your saw blade. I am currently having the best luck with a nice little wooden miter box I got from S.H. Goode & Sons Workshop. I take my picture frame stock and wedge it into place against one side of the box with some pressure sensitive putty adhesive (i.e. blu tack) so its sitting flat with its flange supported so it doesn’t slip out of square and saw away with my fine tooth handsaw. I can usually get the first cut done cleanly, its the second cut that always gives me trouble, hitting the mark and cutting square, ARGHHHH.

Of course, there is always a time element when I’m making picture frames and that doesn’t help any. It usually means I’m a week or two in front of a show and desperate to get things finished. It seems ridiculous to purchase a small table saw, at a cost of several hundred dollars to make frame assembly easier, but at this point, I am seriously contemplating that option. I could also get my stitching done early enough to have frames made for me by someone far less challenged, but I do usually like doing things for myself, and getting things done early? Who’s dreaming there?

Should I just set aside a few days and a few hundred pieces of wood and just practice, practice, practice? It probably would help considerably. Maybe at the end of that, I’d have a few perfect frames and could then stitch to fit the frame…yeah, that’s the ticket!

Anyone out there have any tips to pass on to a miter challenged artist? Tell me how you get your frames to come out perfectly. I’d really appreciate the advice.

The secret has been know for centuries to cabinet makers it is called a shooting board.

A plane or sanding block used with a shooting board jig takes off the last micro amount of variation from a sawed angle to create that perfect and smooth joint.